Special advantages of both materials combined cost-effectively

A Rubber-Metal Seal is a sealing element that combines the advantages of elastomer seals with the material properties of metals. To achieve this, a metal ring is vulcanized into the elastic sealing element, which gives the seal the necessary rigidity. Such elements are needed

- in mechanical and apparatus engineering for the mechanical decoupling of various plant components,

- in pipeline construction to realize robust seals in gas and liquid pipelines as well as

- in the construction of high-pressure plants, where stronger seals than pure elastomer elements are required.

The company Sattler SCM has many years of experience in the development and production of Rubber-Metal Seals. Rubber-to-metal seals have been developed for very special applications. Learn more here about the possibilities and applications of rubber-to-metal seals and about the excellent mechanical and physical properties of these workpieces.

Contact now

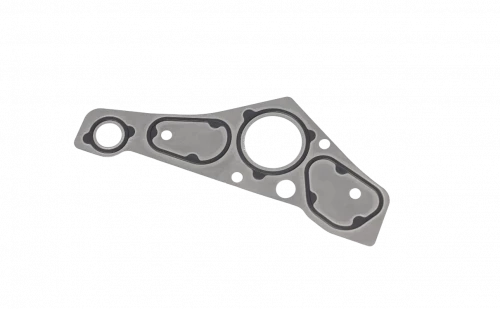

| Application: | Engines; Intake |

| Material: | FKM (Viton) |

| Color: | selectable |

| Dimensions: | 62 x 45 x 2mm |

| Branche: | Automotive |

| Quantity: | 800.000 pieces/ a |

| Engineering: | Metal adhesion with primer |

| Procurement: | Basis Asia |

| Logistics: | Consignment store |