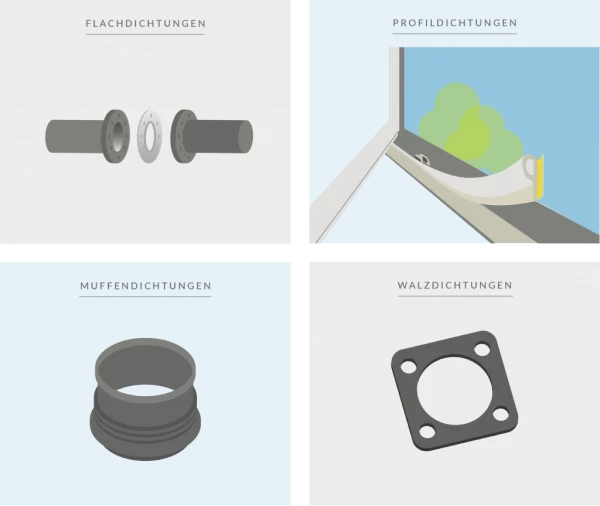

What are the application areas for seals?

The areas of application for our products are as varied as the sealing materials. For example, you will find seals in the construction industry for doors and windows as well as the sanitary sector, in automotive and mechanical engineering, and in the chemical and food industries.

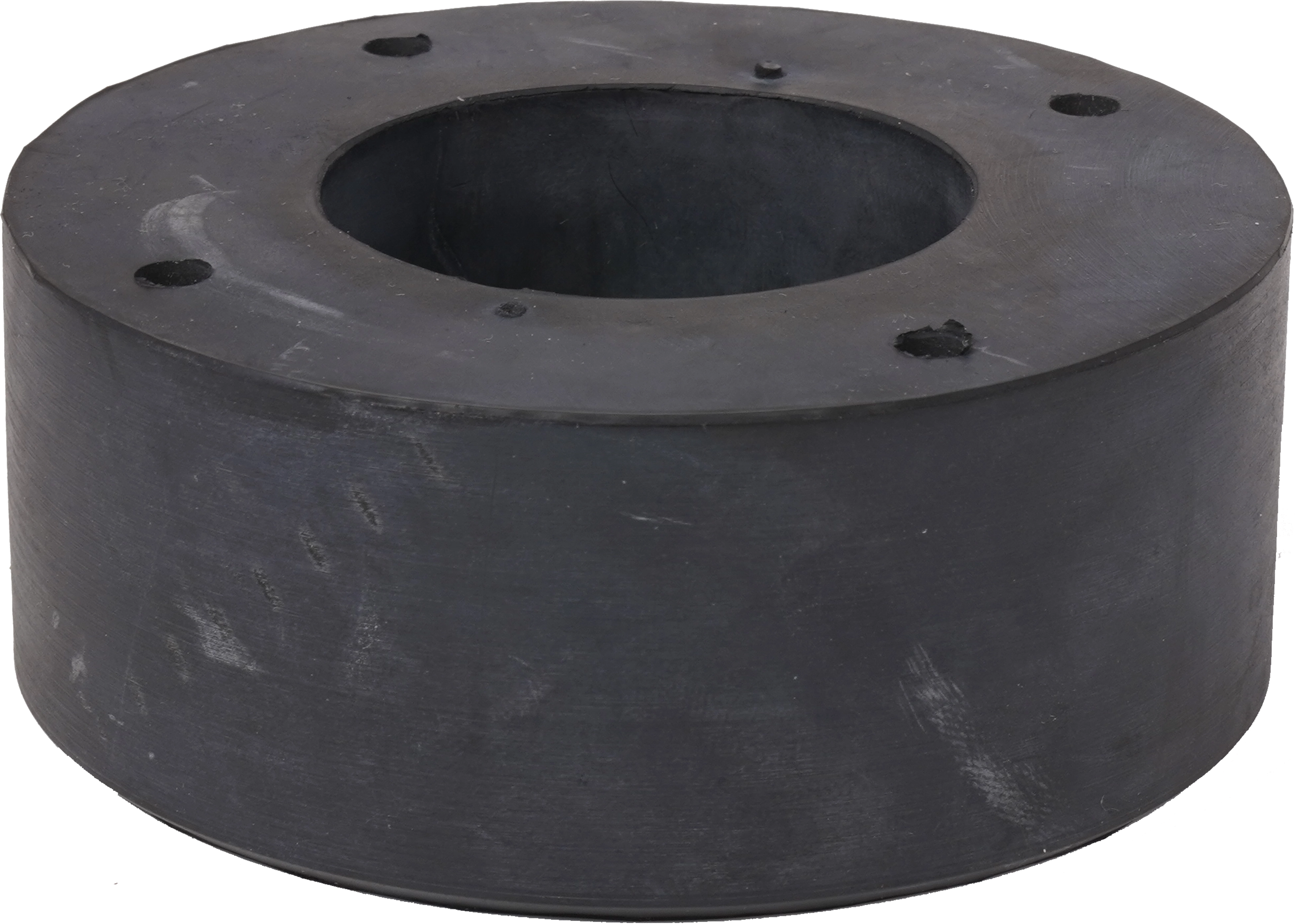

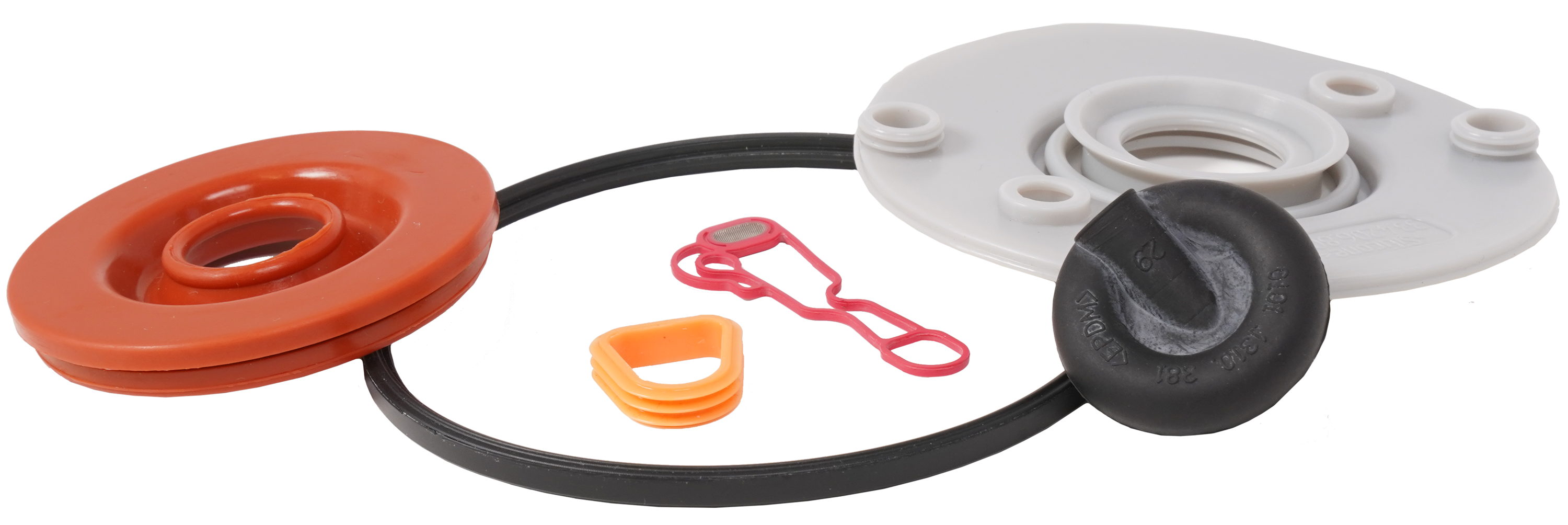

Seals in the sanitary sector

What would faucets, siphons, showers and bathtubs be without seals? If you don't want to experience any nasty surprises due to water damage, you should rely on high-quality seals in the sanitary sector.

Seals for windows & doors

No house or apartment is rented out without an energy certificate. At the same time, improperly sealed windows and doors represent the biggest cold bridge. Perfect window seals save money and enhance the energy efficiency of any property.