Static seals

Static seals are usually designed as contact seals and do not perform any movements themselves. Rather, they serve to reliably compensate for the relative movements of the adjacent workpieces in such a way that no gas or liquid exchange with the environment can be observed.

The following basic forms are used as static gaskets:

- Flat gaskets are made from a variety of materials and are used primarily in pipeline and apparatus construction.

- Profile gaskets owe their name to their distinctive cross-sectional profile and are becoming increasingly important in thermal insulation.

- Socket gaskets facilitate the transition between different pipe diameters.

- Rolled gaskets are made from a variety of heavy-duty materials.

Dynamic seals

A dynamic seal also connects two elements, but carries out movements itself. These movements can be of a translational nature, i.e. force-transmitting along an axis, or of a rotational nature, around a central axis.

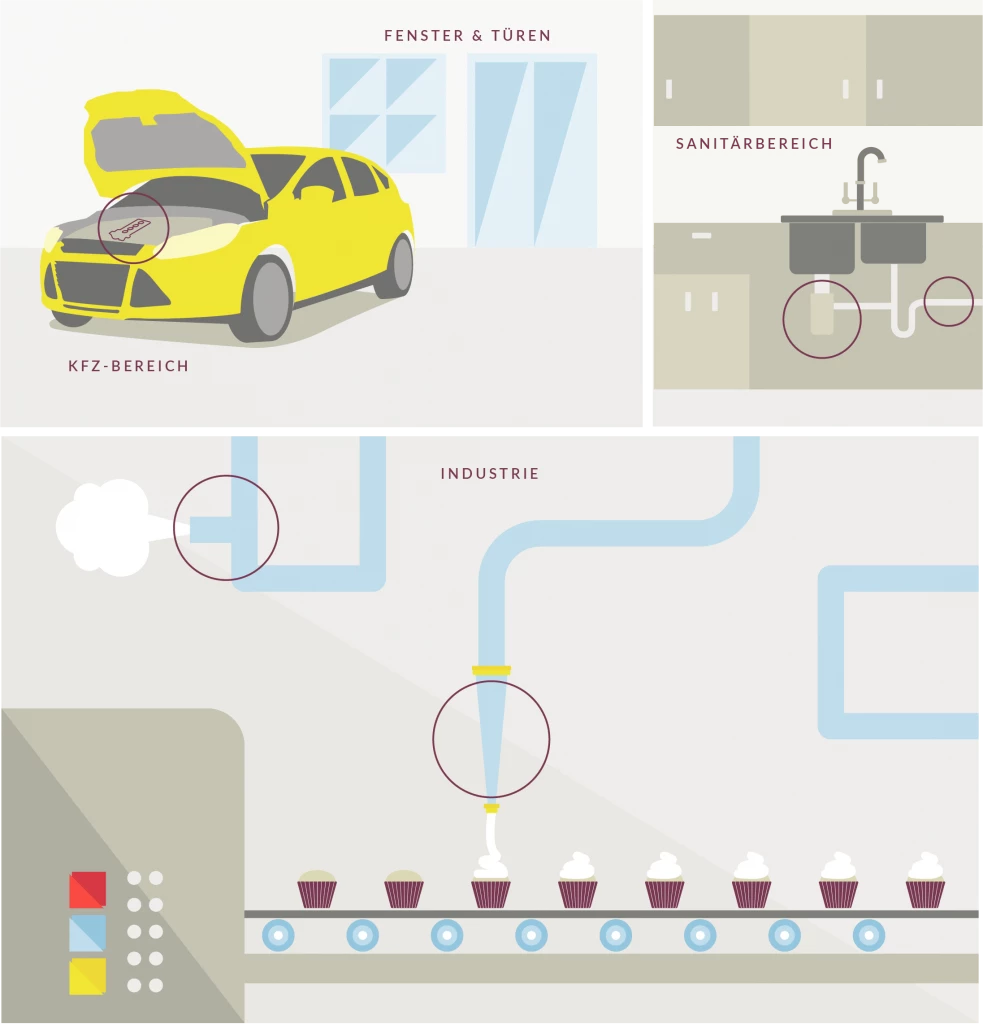

Dynamic seals are used for a wide variety of purposes. This type of seal includes such products as bellows or brush seals.

- A stuffing box seals a rotating shaft against the leakage of lubricant and against the effects of dirt and water vapor.

- Piston rings are important sealing elements in the combustion chamber of an engine that have to withstand the highest loads.

- Many customers are familiar with bellows from buses and trains. We supply bellows in almost all dimensions from large to small. A bellows protects moving machine parts from dirt and moisture.

- A brush seal consists of a bundle of thousands of fibers that lie tightly against the surface to be sealed. Brush seals are increasingly used in engines and turbines, where they have replaced the labyrinth seals that were frequently used until then. Brush seals have a very low leakage rate.

- Hydraulic seals are used in hydraulic cylinders, where they prevent leakage of the hydraulic fluid and at the same time allow smooth translatory stroke movement of the piston.

- A similar task is performed by the pneumatic seal, which effectively prevents the loss of compressed air in pneumatic systems while allowing proper clearance of the pneumatic piston.

- A carbon lamella, also known as a carbon separator, separates the rotor from the housing chamber in pumps and compressors. Carbon has proven itself here as a low-wear material with an excellent coefficient of friction.

Non-contact seals

Non-contact seals are mainly used as dynamic seals when it is necessary that a small gap cross-sintt remains between the seal and the machine part. The sealing effect of a non-contact seal is therefore never perfect due to its design.

Small quantities of lubricants and operating fluids can always escape through the gap between the seal and the component. A non-contact seal must therefore be designed in such a way that it enables the greatest possible sealing effect with the smallest possible obstruction to movement.

A distinction is made between the following types of seals:

- Pressure and throttle seals - such as labyrinth and chamber seals

- Mass-force seals - such as flinger discs and splash rings

- Viscous seals - in this case mainly shaft seals